Smart Sourcing: Time to Lay off the Bottlenecks

13. January 2023

It’s almost three years since the chip shortage surfaced. And many companies just seem to “make do”, but that doesn’t have to be the case. We help to show companies how they can turn challenge into opportunity and thrive in a new market environment.

No one could foresee the pandemic and the resulting collapse of global supply chains. There was a lot of finger-pointing between government and industrial actors, as both fumbled for a solution. Politicians were accused of not having laid down a crisis-proof framework and of a lack of support for companies. The criticism of business, on the other hand, related to the lack of operational risk management.

What really caused supply chains’ downfall however was a sheer lack of resilience and overcomplex processes. The pandemic has only exposed the existing problems. These are particularly evident in the semiconductor market, which is why the world is still reeling from the chip crisis. To understand how companies can survive despite the shortage in the market, a more detailed look at the structure of the semiconductor supply chain is needed.

The Complexities of the Semiconductor Market

Breaking the supply chain down as much as possible, you could argue there are two main links the chip must pass through before reaching end user’s device or equipment. These are the producer and the assembler.

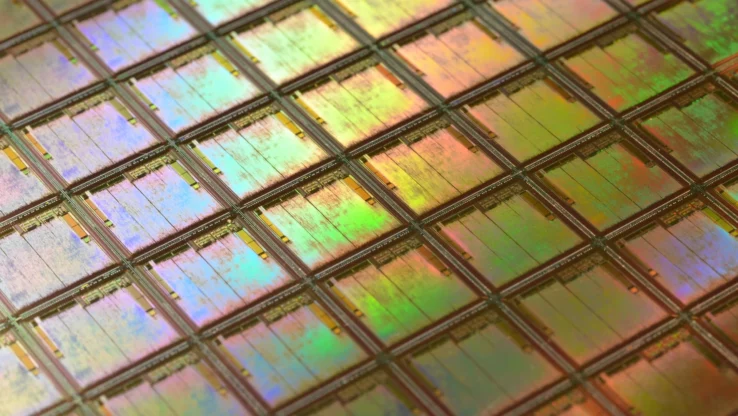

Producers extract quartz sand in complex chemical and physical processes to produce silicon ingots, which are sliced into wafers. Microstructures are lasered onto the surface of the wafer before being punched out. Once the semiconductor has arrived at the assembler, also known as the supplier, the chip is assembled into specific modules. These are then delivered to the end customer, for example, an automobile manufacturer or a provider of hospital equipment. The latter, in turn, installs the assemblies in the products that consumers can then purchase in regular stores.

Consequently, this means that assemblers are an unavoidable entity in the semiconductor supply chain semiconductor, sitting between the chip manufacturer and the company installing the final product. As a result, end customers have no way of influencing the supply chain in any way – not even in the event of a crisis. This makes it difficult to respond to strong fluctuations in demand. This often results in delivery delays, halted production, and lost sales.

Is Strategic Procurement Management the Solution?

But living with the chip crisis is possible if dependencies within the supply chain shift. A well-thought-out procurement strategy breaks up rigid supply chain structures. This makes companies more flexible and independent, and supply more reliable.

Companies can rely on experienced partners for rolling out such a strategy. Sourcing specialists. They stand alongside the semiconductor supply chain as an independent entity, which means they are flexible and not bound to rigid structures. They have an overview of the current situation on the market, are well networked and are well informed about the order status at the producer, assembler, and end customer. This enables them to act immediately across the supply chain as soon as there are signs of bottlenecks. They usually have branches in strategically favorable locations and are networked with various chip producers.

The Secret Source

In order to remain flexible, sourcing specialists rely not only on producers but also on brokers and distributors for the procurement of semiconductors. This degree of variance ensures chip supply even in the event of a crisis or supply bottlenecks. A few also rely on “alternative sourcing” – the alternative procurement of equivalent parts from other manufacturers whose functionality and structure meet the requirements.

For automotive manufacturers in particular, whose position at the end of the supply chain means they have little influence on chip delivery, a partnership with sourcing specialists can make a significant contribution to success in the market. Instead of being unable to act in times of shortage, companies can act in a self-determined manner. This makes the entire semiconductor supply chain more resilient and can prevent the next global crisis.

However, in order to be able to address all eventualities and possible developments, it is essential to take a look at the future of the chip market. You can find out more about this in the third part of our series surrounding the semiconductor market.