Committed to Quality

Our team combines years of experience with deep technical expertise. We work to the highest quality standards to test your components safely and reliably—with precision, transparency, and full independence.

Meet the SI TechLAB Team

At the SI TechLAB, experts in materials engineering, semiconductor physics, polymer science, electronics, and quality management work side by side. What unites us? A shared passion for reliable results. We develop testing procedures, interpret borderline cases, and ensure quality — from the initial concern to the final test report. By combining scientific precision with industrial pragmatism, we deliver dependable answers.

Insights from the SI TechLAB

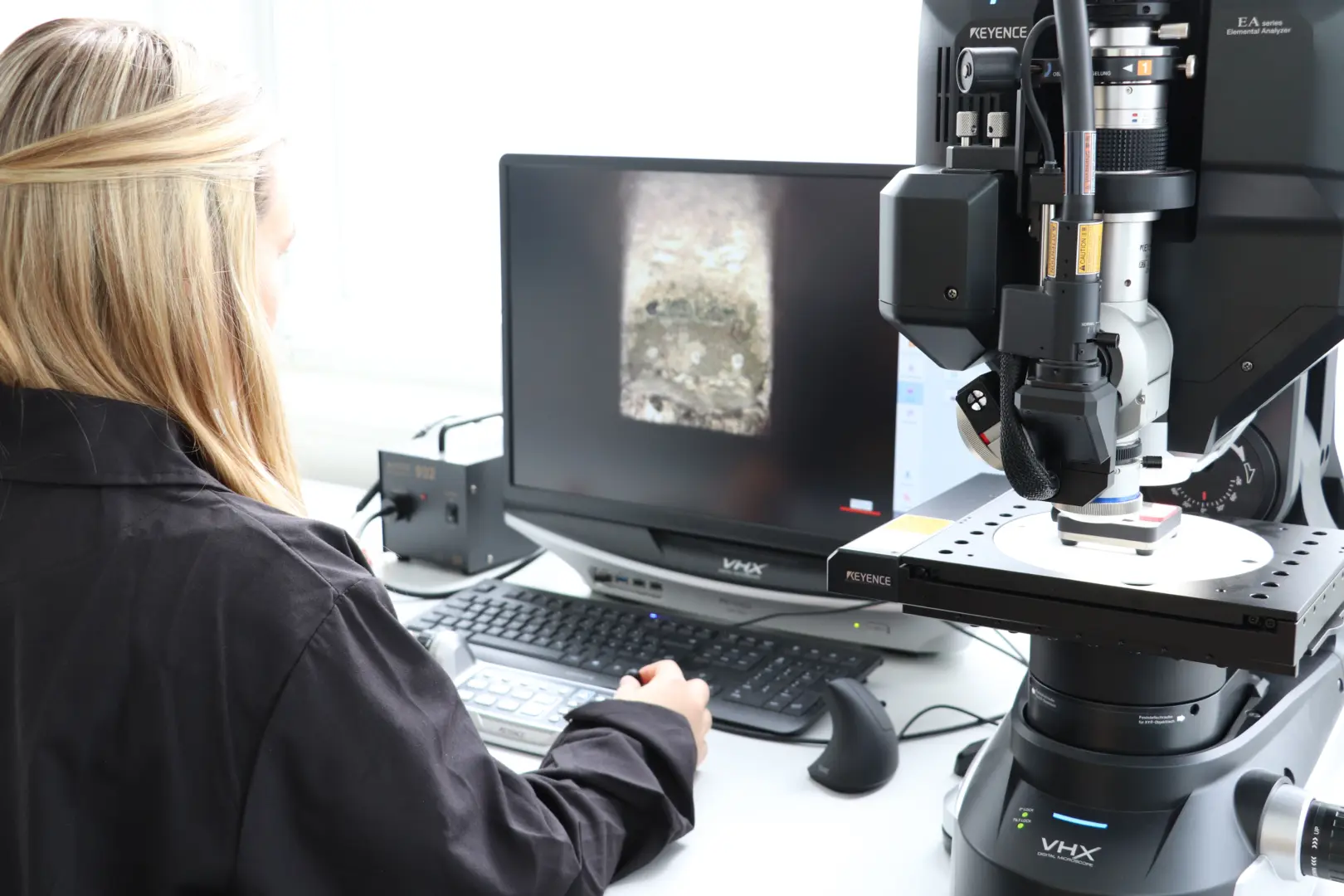

Interview: Alina Kleiber

As senior lab technician, Alina ensures that our customers receive only high-quality components. In our testing lab, she works with state-of-the-art equipment.

In this video, Alina provides a behind-the-scenes look at her fascinating daily work and demonstrates the advanced tools and techniques she uses. Find out what makes SI Electronics an exciting and attractive place to work.

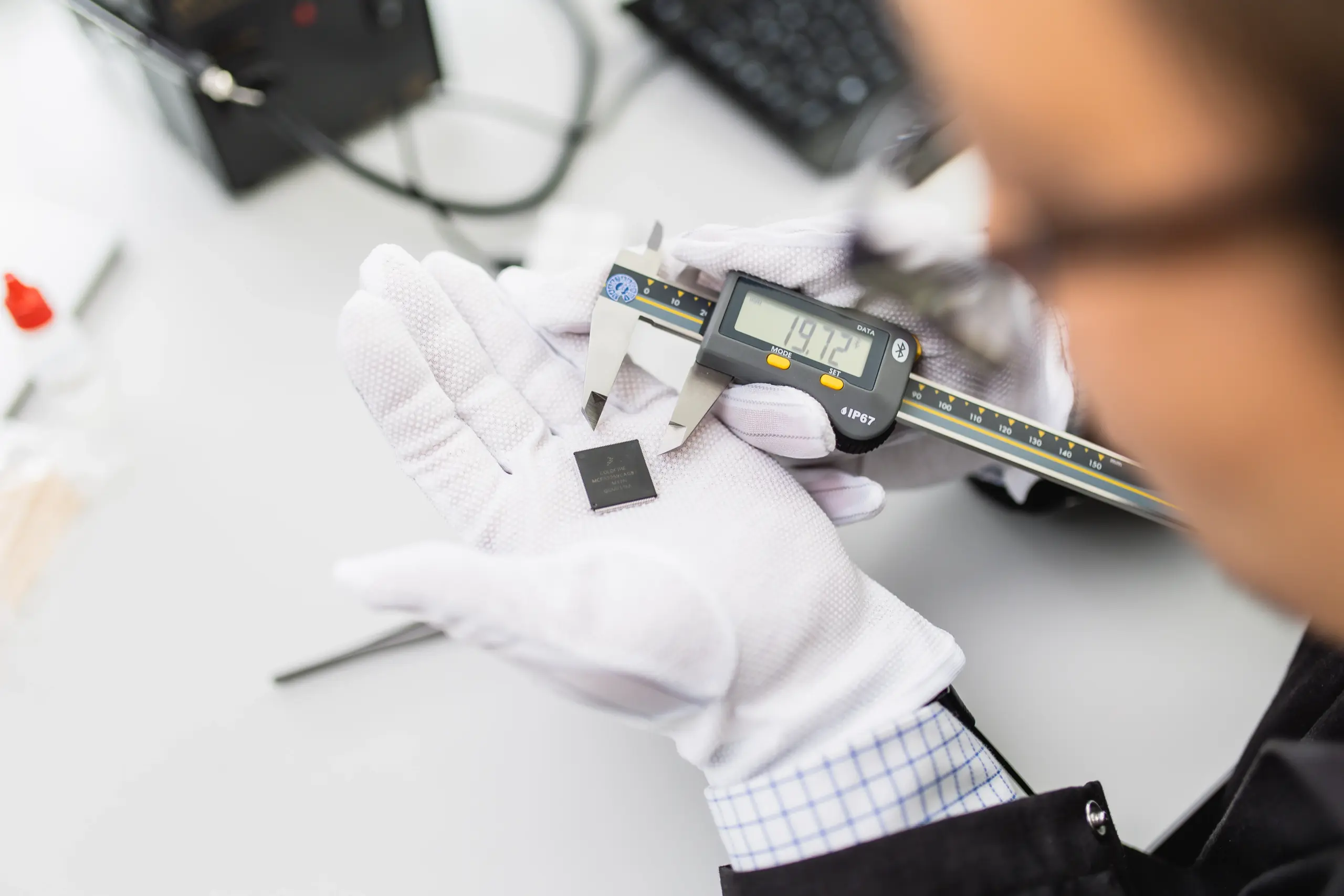

What Sets Us Apart: Precision in Every Step

At SI Electronics, technical testing isn’t an add-on; it’s integral to everything we do. Our scientifically trained specialists combine state-of-the-art laboratory technology with extensive knowledge of high-reliability components. This is how we ensure the quality and authenticity of your parts.

1

Technical Pre-Assessment with Substance

We don’t speak in buzzwords; we speak in technical terms. Even before the quotation phase, we work closely with our customers to thoroughly, transparently, and solution-focused analyze the issue at hand.

2

Fast Execution — Even for Special Cases

Our automated standard processes allow us to complete many testing assignments in just a few days. Even for complex or unusual cases, we typically deliver results within five business days.

3

Cutting-edge Technology Yields Clear, Differentiated Results

4

Tailored Testing Concepts for Special Requirements

Not every technical issue can be addressed with standard methods. For complex components, unclear damage patterns, or specific use cases, we design custom testing setups that are sound, traceable, and precisely aligned with the application.

Our Publications

We actively contribute to the industry dialogue through technical journals, conferences, and white papers. After all, those who test should also be transparent about how they think, how they work, and how they deliver reliable results.

FTIR Spectroscopy

Counterfeit microchips pose a growing threat to the electronics industry. Advanced analytical methods, such as FTIR spectroscopy, can uncover even sophisticated forgeries, including recycled or altered components. Learn how this technology helps safeguard the integrity of electronic parts.

Long-Term Storage

Global crises, such as political tensions and natural disasters, reveal the vulnerability of international supply chains. Companies that prepare early for such disruptions can avoid production downtime and maintain their competitive edge. Discover why forward-thinking planning is essential in electronics manufacturing.

When Will You Put Us to the Test?

Our team is here for you, offering tailored testing concepts and scientifically grounded analyses. Contact us today or call us directly:

+49 621 405406-80