SI TechLAB

Your lab for precise, fast, and independent component analysis.

Quality Assurance for Your Supply Chain

Global supply chains pose risks: questionable sources, counterfeit components, and time pressure in production. Our services address these risks early through testing, documentation, and technical solutions that reveal potential issues before they escalate into problems.

Whether as your lab partner, technical inspection body, or innovation space for complex challenges, the SI TechLAB stands for clarity.

Our Services at a Glance

Component Testing and Authentication

Counterfeit or tampered components pose significant risks to quality, safety, and product liability. At the SI TechLAB, we develop customized authentication processes for electronic components based on industry standards, such as IDEA-STD-1010, AS6081, and AS6171. Our processes are supported by proven methodologies and executed with technical flexibility. This ensures clarity before critical components are put into use.

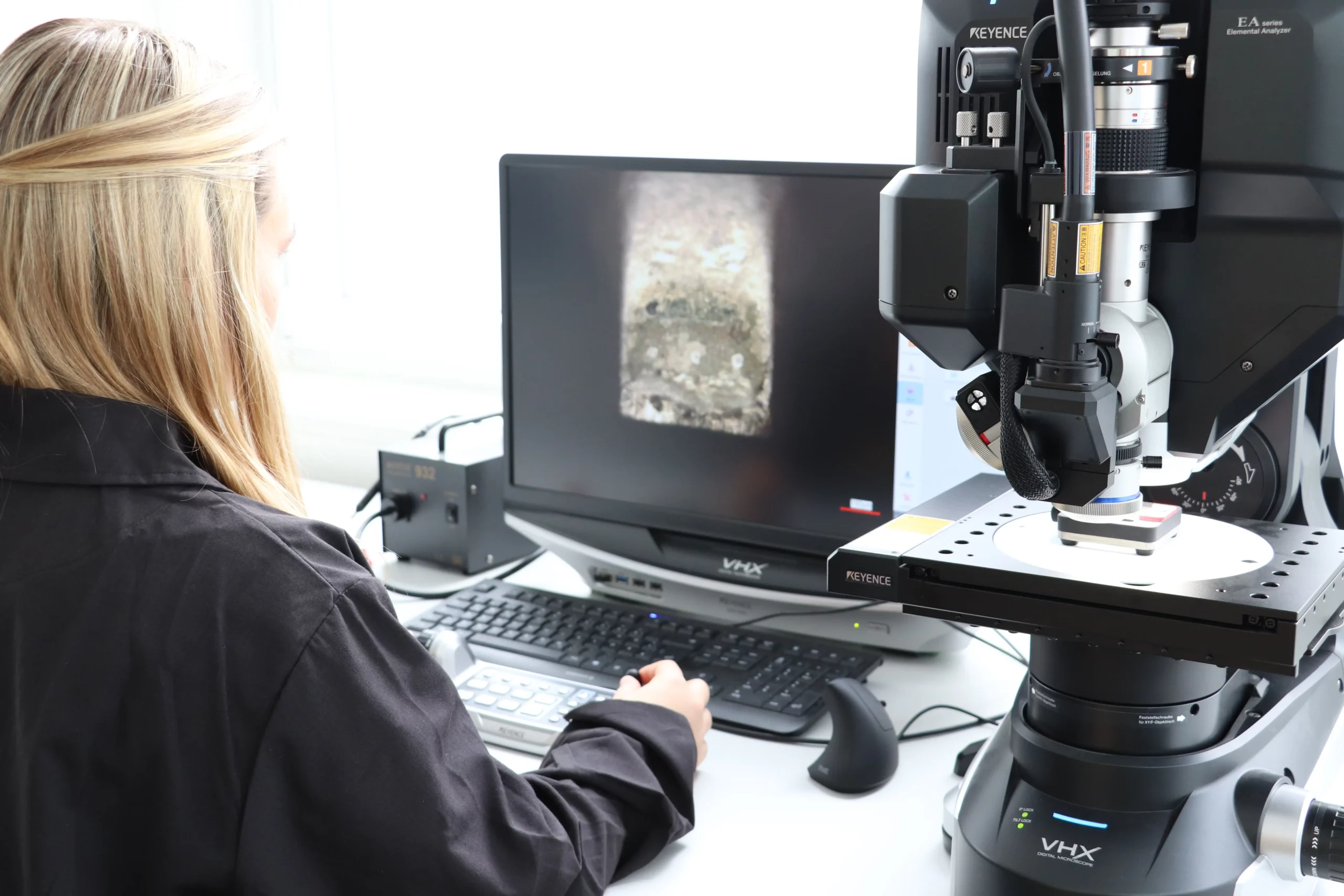

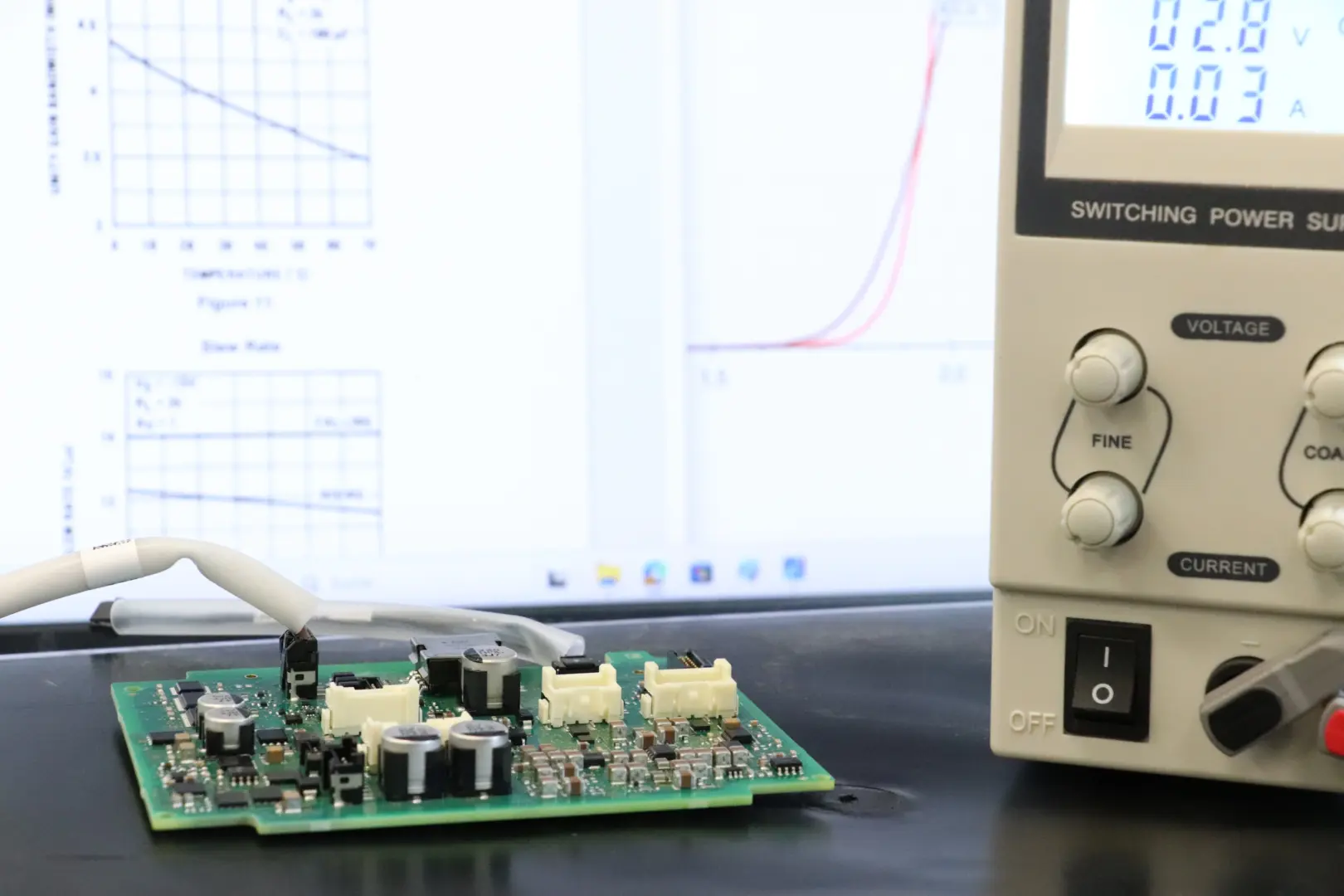

Failure and Damage Analysis

When assemblies fail, every detail matters. We analyze damage patterns using microscopy, electrical testing, and X-ray inspection — systematically and efficiently, focusing on what truly counts. Want to follow the process live? Just book a remote session and join us in real time via a microscope feed, including a discussion of the results with our experts.

In-Line Quality Monitoring for Series Production

We detect anomalies, deviations, and potential sources of failure early on with our tailored testing processes for your production series. Whether we’re examining microscopic structures, using X-ray imaging, or conducting material analysis, we work with you to develop the right approach — one that’s fast, efficient, and cost-effective.

For production runs that keep moving — not stalling.

Long-Term Storage

We provide optimal storage conditions for sensitive components, including an inert gas atmosphere, temperature control, and full documentation. Our processes include FTIR analysis, solderability testing, and visual inspections to ensure long-term processability and reliability.

For quality that lasts — and is fully traceable.

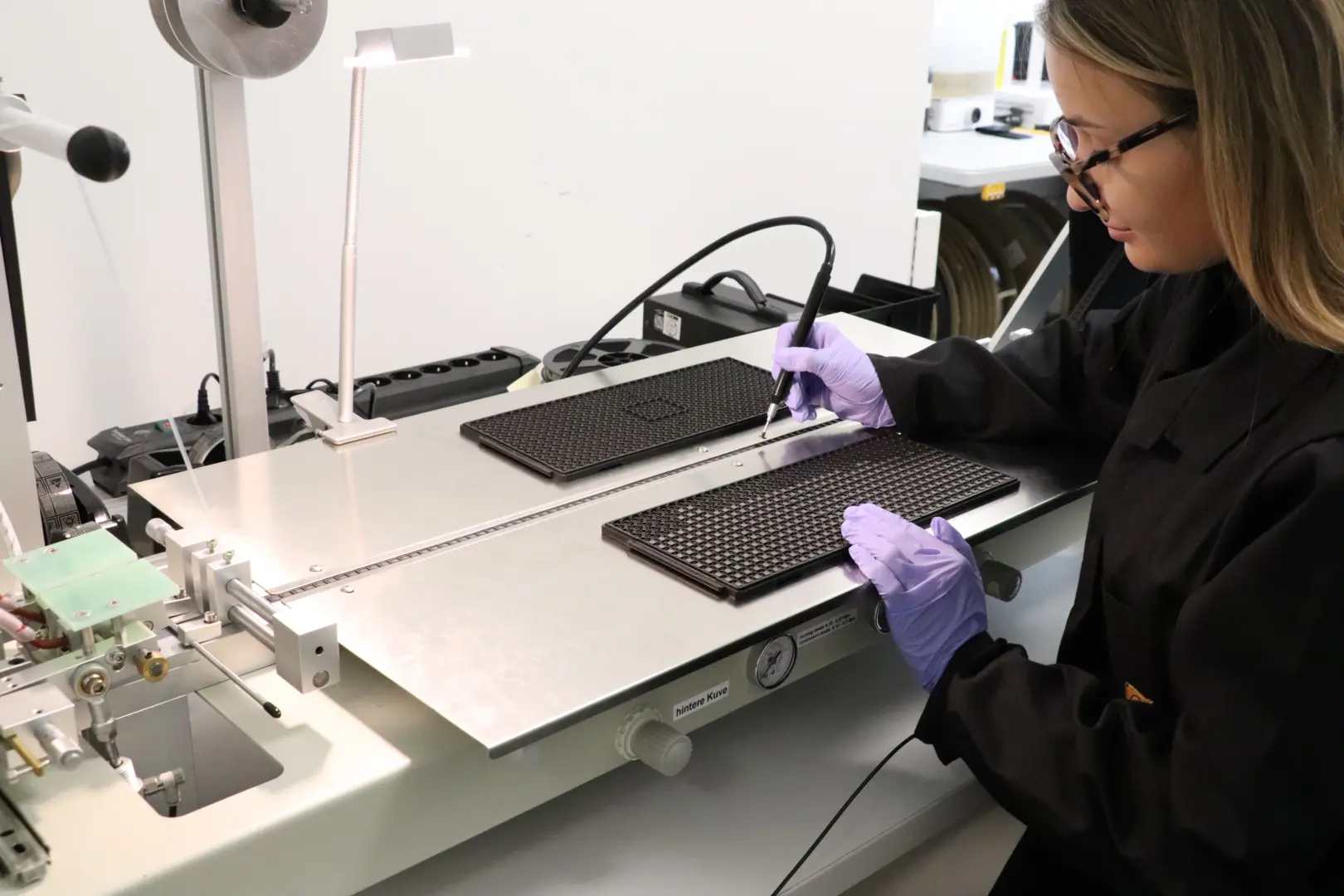

Taping, Packaging, and Drying

We prepare components for processing by taping, relabeling, vacuum packaging, re-drying according to MSL classification, and storing in a humidity-controlled environment. We also assemble custom repair kits tailored to your needs.

This ensures that your electronics arrive exactly where they’re needed—on the production line—ready to go.

Structured Testing for Maximum Reliability

Our testing program, which includes everything from incoming inspection to decapsulation, is modular, risk-based, and fully documented. Whether your requirements are standardized or customized, we deliver transparency and quality before production even begins.

Our Team: Expertise That Makes the Difference

Our testing follows clear procedures, but true assurance comes from experience. Our team of engineers and materials and semiconductor technology experts combine technical judgment with industrial precision.

Are You Ready for Precise Component Testing?

We’re here to support you with expert advice on technical questions, testing strategies, and urgent failure analysis. Send us a message or call us directly:

+49 621 405406-80